How do mist disinfecting nozzles work

The mist disinfection nozzle is formed by dispersing the liquid under pressure. The misting disinfection nozzle ejects the liquid in the form of atomizing. It is a disinfection nozzle product evenly suspended in the air.

The working principle of misting disinfection nozzles

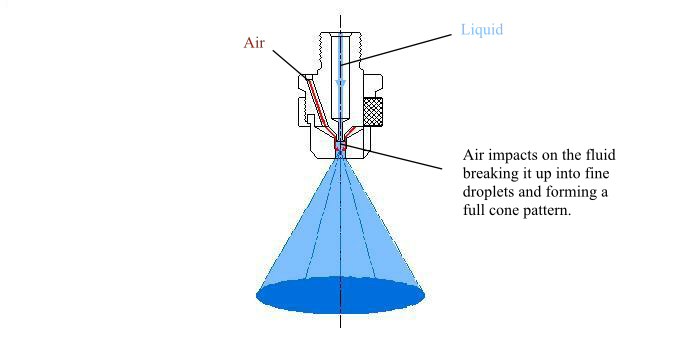

Mist disinfection spray nozzle working principle of the products is water through the nozzle, through the edge of the nozzle hole expansion to the liquid layer, due to the aerodynamic instability, the liquid layer cracks become elongated tube hole shape thick cylinder, into droplets, the diameter of the droplet intrusive depends on the liquid layer thickness and evenness, stable liquid and rupture process.

The working principle of the misting disinfection nozzle is to press the internal liquid into the nozzle through the internal pressure, and the blade is placed inside the atomizing nozzle. The high-speed liquid forms the fog through the swirling cavity of the blade and the huge thickness of the blade.

The nozzle aperture of the disinfection nozzle must be matched with the nozzle, so that after the impact of the liquid rebound, the diameter of 15-60 microns or so is composed of atomized particles, and the spray is formed through the nozzle of the disinfection nozzle.

Disinfecting nozzles atomize the liquid in the process of breaking it down into small drops of water, known as drops, drops or liquid particles.

Each spray must have droplets of very small size, rather than uniform droplets of the same diameter.

The scale of droplet scale is related to the properties of the fluid, the type of the nozzle and the injection function and the injection pressure, as well as the injection view point.

The wear of atomizing and disinfecting nozzle is mainly manifested as the addition of nozzle flow and the abnormity of the same shape as the nozzle.

Flat, fan-shaped sprinkler heads with elliptical sprinkler heads become narrower as they wear out.

The additional nozzle flow is usually with the decrease of the system pressure, the use of positive displacement pump system in particular.

The way to improve atomization of misting disinfection nozzles

(1) Increase the gas-liquid phase velocity difference of the atomizing disinfection nozzle, increase the aerodynamic force, so that the droplets are broken into finer particles under more atmospheric dynamics.

Simple understanding is to increase the pressure of the atomizing disinfection nozzle to make the spray smaller.

(2) Increase the exit speed of the liquid misting disinfection nozzle to enhance the collision, so that the relatively ejected droplets are further broken in the collision process.

If the droplet exit velocity is small, the larger droplets will aggregate, while if the droplet exit velocity is high, the atomization degree can be increased.

However, this reduces the relative velocity of the gas and liquid and makes the aerodynamically misted droplets worse.

(3) The geometric shape and size of misting disinfection nozzle and mixing pipe also have a great influence on the atomizing performance of atomizing nozzle.

Therefore, in the design of misting nozzle model, in addition to considering their influence on atomization, we should also consider the overall performance changes after their combination, in order to achieve the best atomizing effect.

(4) To study the relationship between the flow and pressure of the spray water supply system of the atomizing disinfection nozzle and the geometric size and structure of the nozzle, so as to improve the atomizing effect.

Especially the water pressure of the water supply system has a greater influence on the misting effect.

The higher the water pressure, the finer the water mist particles.

But the problem with higher water pressure is:

① High energy consumption;

② All parts of the water supply system are under pressure, which is prone to failure and has a short life, especially the spraying system inside the mine equipment.

How to improve the structure of pressure misting disinfection nozzle to obtain fine water spray particles under limited water supply pressure will be a problem that we need to continue to study and discuss in the future.

We believe that under the continuous experiment and research of our technical personnel, this problem will be solved very well.

It's just a matter of time and sustained experimentation.

Now we have some understanding of how misting disinfection nozzle work.

But because misting disinfection nozzle can be applied to many industries or equipment, each equipment has different requirements for misting disinfection nozzle.

So we can according to the actual use of the situation to learn more about the knowledge of misting disinfection nozzle.