Disinfection nozzle common problems and solutions

Disinfection Nozzle, in the long-term use of the process will inevitably encounter different problems, we need to deal with.

We specially collected some common problems and solutions of the disinfection nozzle for you. Now let's take a look at what problems there are and how to deal with these problems.

1. Nozzle infarction

Treatment: Nozzle infarction, is one of the most common problems we use the disinfection nozzle.When we meet the appropriate disinfection nozzle infarction, we need to clear the dirt and impurities inside the disinfection nozzle, adhere to the cleaning of the nozzle inside.

However, some customers in order not to let the nozzle attack infarction, developed a regular cleaning nozzle program or the use of spiral nozzle (spiral nozzle is not easy to infarct characteristics), these are feasible methods.

2. Temperature damage

Disinfection Nozzle material is not the same, its ability to resist high temperature is not the same.If we choose the disinfection nozzle needs to be used to the high temperature environment, then we have to think about the disinfection nozzle material, the general proposal to use stainless steel, brass, ceramic and other high temperature resistant material, plastic material must not choose.

Because the plastic nozzle is easy to be deformed due to high temperature, thus affecting the spray effect of the nozzle.

3. Corrosion of nozzle

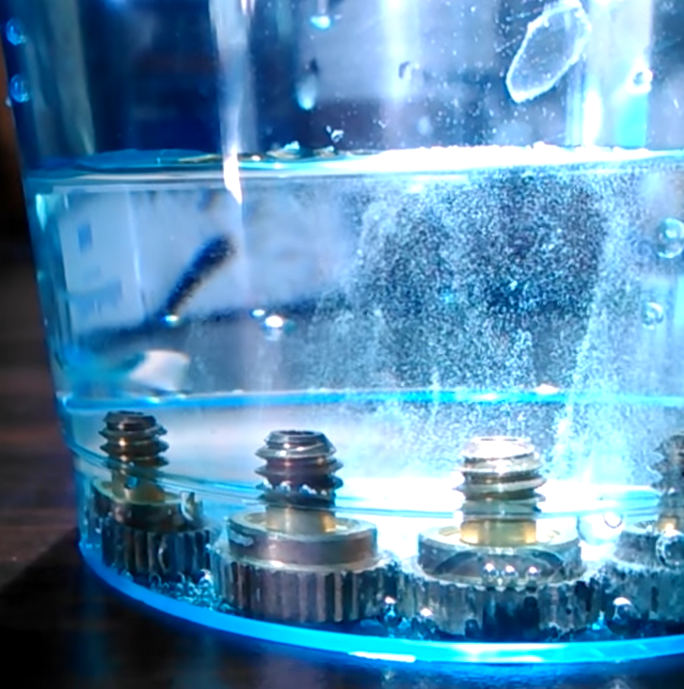

If the liquid sprayed by the disinfection nozzle has a strong chemical property, then when we choose the disinfection nozzle, we also need to pay attention to the choice of the disinfection nozzle material. It is necessary to choose the material that is not easy to attack the chemical reaction.Stainless steel spiral nozzle is relatively easy to attack corrosion and other conditions, so when you choose the nozzle, we must pay attention to, really do not understand, can consult us.

4. Wear and tear of nozzle

Wear and tear of the disinfection nozzle, which cannot be prevented.No matter which disinfection nozzle you use, which material nozzle, more or less there is wear and tear.

Of course, when choosing disinfection nozzle material, or choose those wear-resistant materials like stainless steel nozzle.

If the nozzle is badly worn, we can only change a new nozzle, replace the original nozzle to stop the spray work.

5. Other reasons

In fact, there are many problems that the disinfection nozzle can not work properly. For example, the disinfection nozzle is not well equipped, resulting in the spray work can not stop or the spray effect is poor.Feel free to contact us if you have any questions.