Droplet Diameters Measurement Technology

The droplet size distribution in sprays is one of the vital parameters required for fundamental analysis of practical sprays. Many spray applications such as evaporative cooling, gas conditioning, fire suppression, spray drying and agricultural spraying rely on this information for effective use. The droplet diameter distribution data can usually be obtained through accurate measurement techniques under stable operating conditions. At present, many technical methods for droplet size testing have been developed. Most of these use optical methods to characterize sprays. The following is an overview of testing procedures and the most popular drop size analyzers.

This type of analyzer is still in use. Initially, availability of these instruments was limited and prevented researchers and other interested members of the drop size analysis community from verifying data from different sources and comparing performance from similar nozzle designs.

The collected droplets will be quickly deposited in the silicone oil, and will not evaporate and be photographed even under strong light. They are still suspended in silicone oil and are measured as perfect spheres. The immersion sampling method is mainly used to measure droplet diameter sprayed of hydraulic nozzles.

This instrument is best suited for measuring small capacity two-fluid, hydraulic and flat spray nozzles and is useful for comparisons and quick evaluation of prototype nozzles. The most serious limitation of this technique is known as multiple scattering. Multiple scattering occurs when spray densities are too high resulting in the light being scattered by multiple drops before reaching the detector. The most common laser diffraction instrument in use today is the Malvern analyzer.

Figure 6: Phase Doppler analyzer

The scattered interference sweeps past the receiver unit at the Doppler difference frequency, which is proportional to the drop velocity. The spatial frequency of the fringe pattern is inversely proportional to the drop diameter. A data analysis routine is used to convert the raw drop count into a meaningful drop size distribution. The PDPA measures sizes in the 0.5 to 10,000 μm range using various optical configurations.

The PDPA is best suited for two-fluid, hydraulic and flat spray nozzles in every capacity. It is ideal for complete spray evaluation and where drop velocities are required

DV0.5: Volume Median Diameter (also known as VMD or MVD). A means of expressing drop size in terms of the volume of liquid sprayed. The VMD is a value where 50% of the total volume (or mass) of liquid sprayed is made up of drops with diameters larger than the median value and 50% smaller than the median value. This is best used for comparing the average drop size from various analyzers.

DV0.1: A value where 10% of the total volume (or mass) of liquid sprayed is made up of drops with diameters smaller or equal to this value. This diameter is best suited to evaluate drift potential of individual drops.

DV0.9: A value where 90% of the total volume (or mass) of liquid sprayed is made up of drops with diameters smaller or equal to this value. This measurement is best suited when complete evaporation of the spray is required.

D32: Sauter Mean Diameter (also known as SMD) is a means of expressing the fineness of a spray in terms of the surface area produced by the spray. SMD is the diameter of a drop having the same volume to surface area ratio as the total volume of all the drops to the total surface area of all the drops. This diameter is best suited to calculate the efficiency and mass transfer rates in chemical reactions.

D43: Herdan diameter. This diameter is best suited for combustion studies.

In chemical processes such as cooling, evaporation, combustion and drying, it is common to determine efficiency using the ratio of volume-surface area, i.e. specific surface.

Because a small portion of large droplets is more influential over the rate of reaction than a large portion of small droplets, it is advisable to use Sauter Mean Droplet Diameter(D32) as representative droplet sizes.

-

Introduction to Measurement Technology

a ) Optical imaging analyzers

Optical imaging analyzers incorporate the spatial measurement technique. These analyzers consist of a light source (typically a strobe light or laser), video camera and computer. The light is used to illuminate the spray; which is recorded using the video camera. The image is then scanned and the drops are sized and separated into different classes. Sources of error early in the development of this device included blurring, depth of field variations and improper sample size. These error sources have been recognized and corrected.This type of analyzer is still in use. Initially, availability of these instruments was limited and prevented researchers and other interested members of the drop size analysis community from verifying data from different sources and comparing performance from similar nozzle designs.

Figure 1: Optical imaging analyzer

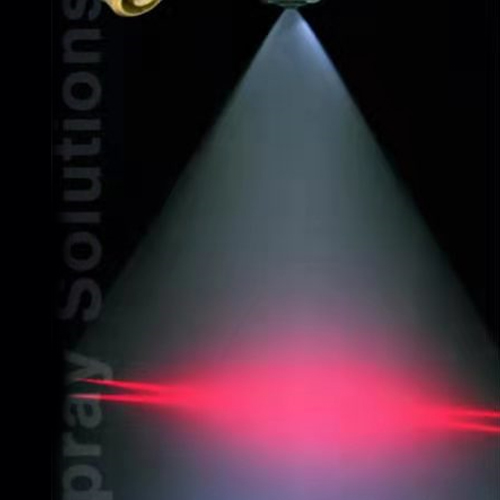

b) Immersion Sampling Method

The immersion sampling method is to collect the droplets on a glass plate thickly coated with silicone oil, and immediately take pictures at high magnification for subsequent counting by size.

Figure 2: Immersion sampling method

The collected droplets will be quickly deposited in the silicone oil, and will not evaporate and be photographed even under strong light. They are still suspended in silicone oil and are measured as perfect spheres. The immersion sampling method is mainly used to measure droplet diameter sprayed of hydraulic nozzles.

Figure 3: Immersion sampling method

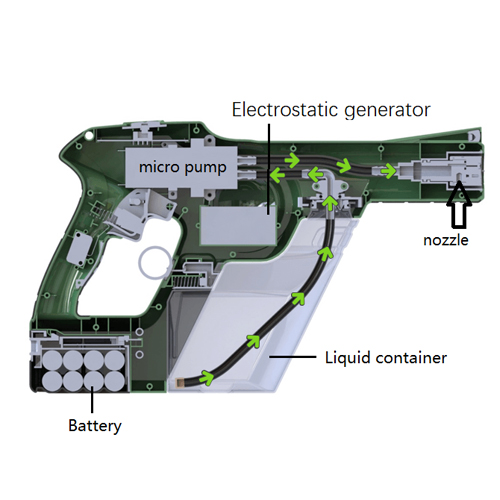

c)Laser diffraction analyzers

Laser diffraction analyzers are also spatial sampling devices but fall into the non-imaging (ensemble) category. These analyzers consist of a transmitter, receiver and computer. The technique is based on measuring the scattered light intensity caused by the drops as they pass through the analyzer sampling area. A laser beam scatters at the surface of droplets in the laser beam path and the diffraction pattern caused by interference of scattered light is focused behind the droplets. This method can simultaneously measure all droplets in the laser beam path.

Figure 4: Laser diffraction analyzers

The scattered light intensity is measured using a series of semicircular photo-diodes housed in the receiver unit. A curve-fitting program is used to convert the light intensity distribution into any of several empirical drop size distribution functions. The range of instruments using this technique is 1.2 to 1,800 μm.This instrument is best suited for measuring small capacity two-fluid, hydraulic and flat spray nozzles and is useful for comparisons and quick evaluation of prototype nozzles. The most serious limitation of this technique is known as multiple scattering. Multiple scattering occurs when spray densities are too high resulting in the light being scattered by multiple drops before reaching the detector. The most common laser diffraction instrument in use today is the Malvern analyzer.

Figure 5: Laser diffraction analyzers

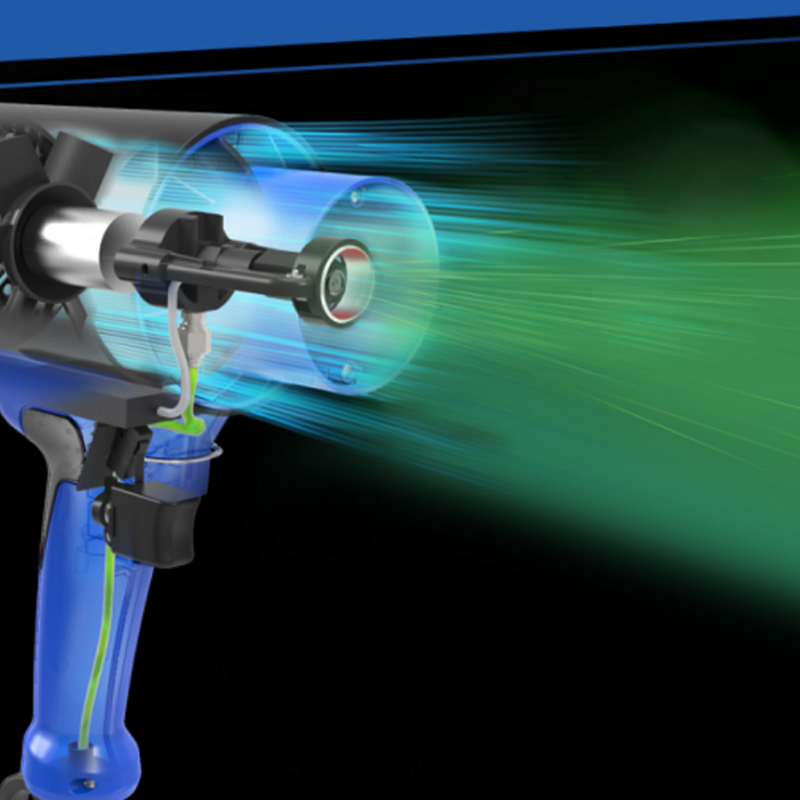

d ) Phase Doppler particle analyzers (PDPA)

PDPA are flux sampling instruments and fall into the non-imaging (single particle counter) category. These analyzers consist of a transmitter, receiver, signal processor and computer. The PDPA uses a low-power laser that is split into two beams or four beams for a 2- dimensional system. By utilizing a beam splitter and frequency module; these laser beams intersect again at a point referred to as the probe volume. When a drop passes through the probe volume, the scattered light forms an interference fringe pattern.Figure 6: Phase Doppler analyzer

The scattered interference sweeps past the receiver unit at the Doppler difference frequency, which is proportional to the drop velocity. The spatial frequency of the fringe pattern is inversely proportional to the drop diameter. A data analysis routine is used to convert the raw drop count into a meaningful drop size distribution. The PDPA measures sizes in the 0.5 to 10,000 μm range using various optical configurations.

The PDPA is best suited for two-fluid, hydraulic and flat spray nozzles in every capacity. It is ideal for complete spray evaluation and where drop velocities are required

-

General Terminology

DV0.5: Volume Median Diameter (also known as VMD or MVD). A means of expressing drop size in terms of the volume of liquid sprayed. The VMD is a value where 50% of the total volume (or mass) of liquid sprayed is made up of drops with diameters larger than the median value and 50% smaller than the median value. This is best used for comparing the average drop size from various analyzers.

DV0.1: A value where 10% of the total volume (or mass) of liquid sprayed is made up of drops with diameters smaller or equal to this value. This diameter is best suited to evaluate drift potential of individual drops.

DV0.9: A value where 90% of the total volume (or mass) of liquid sprayed is made up of drops with diameters smaller or equal to this value. This measurement is best suited when complete evaporation of the spray is required.

D32: Sauter Mean Diameter (also known as SMD) is a means of expressing the fineness of a spray in terms of the surface area produced by the spray. SMD is the diameter of a drop having the same volume to surface area ratio as the total volume of all the drops to the total surface area of all the drops. This diameter is best suited to calculate the efficiency and mass transfer rates in chemical reactions.

D43: Herdan diameter. This diameter is best suited for combustion studies.

In chemical processes such as cooling, evaporation, combustion and drying, it is common to determine efficiency using the ratio of volume-surface area, i.e. specific surface.

Because a small portion of large droplets is more influential over the rate of reaction than a large portion of small droplets, it is advisable to use Sauter Mean Droplet Diameter(D32) as representative droplet sizes.

-

Drop size distribution

Figure 7: Doppler size distribution

-

Droplet analysis technology used on Disinfection and Sterilization